Dredging project underway to rebuild Ocracoke sand dunes and clear ferry channel

An emergency dredging project is underway that aims to accomplish two goals: rebuild the dunes that border the northern end of Ocracoke along N.C. Highway 12, and create a deeper and safer passage for the ferries that regularly run between the Hatteras and Ocracoke ferry terminals.

The clamshell-bucket dredging operation that is currently occurring in the Sloop Channel near northern Ocracoke is a new type of dredging for the islands that has never been conducted before, per North Carolina Department of Transportation (NCDOT) personnel involved in the project. But the ongoing initiative, which will last until the end of March at the earliest, will hopefully create a safer corridor for both highway and ferry travelers, and is an emergency project that had a slow start, but is steadily gaining steam.

N.C. Highway 12 on northern Ocracoke Island is dangerously narrow, and this stretch of roadway is protected by a dune line that has been bolstered with a barricade of sandbags. Per National Park Service guidelines, the sandbag-base is allowed, however, it needs to be covered by a layer of actual sand material, so that the sandbags aren’t exposed, and aren’t the only thin and manmade barrier between the highway and the ocean.

And in the past several months, this has been a problem. Late 2021 and early 2022 saw a number of winter storms – too many to mention – that eroded the sandy layers on top of the sandbags, and left N.C. Highway 12 a storm or two away from being entirely inaccessible.

“Over the winter, we lost cover on our sandbags that was [added] the previous winter,” said Brandon Tatum, Resident Engineer with NCDOT. “Part of our permitting with the NPS is that those bags have to be covered at all times with sand.”

Normally, the NCDOT would collect material from a designated area on Ocracoke for deposited dredge material, (known as a spoil pit), that is located adjacent to the ferry docks. This spoil pit typically contains a stockpile of sand material for exactly these types of maintenance issues. But with multiple storms over the past year, this stockpile has been depleted, and the need for a new solution was imminent.

“The last time we did a similar [dune rebuilding] project, which was last winter, we depleted our sand resource, so the option to dredge came up,” said Tatum.

An emergency contract stemming from one of the past winter storms was initiated, and a contractor was selected to dredge material out of Sloop Channel, transport it to the designated spoil pit, and eventually transport it to the dunes.

On January 6, the NCDOT awarded a contract to McLean Dredging of Baltimore, MD, a company that was familiar with the clamshell bucket-and-barge method that could harvest the sandy material required to replenish the spoil pit supply. In the past, NCDOT and other agencies have used different types of dredging operations to clear the navigational channel, boost the spoil pit materials, or both: these past options included utilizing the US Army Corps of Engineers’ (ACOE) sidecaster dredge, or utilizing a pipeline dredging system.

But because time was of the essence, (and the ACOE’s dredge was unavailable for the timeframe), a new dredging technique was enlisted, which has the potential to resolve shoaling in the Sloop Channel, and create a better barricade for N.C. Highway 12 along Ocracoke Island.

The bucket dredging operation had issues from the get-go, however, due to a series of storms that occurred every weekend since the start of 2022.

The vessels, based in Norfolk, VA, were unable to be transported to the Hatteras Inlet area until January 28, which was the first day of dredging.

Essentially, the way the process works is that the “clam-shell bucket” of the crane goes down into a specific area, scoops up material, and deposits the material onto an adjacent barge after the excess water has sifted through the airborne bucket, leaving only sand behind.

This part of the process takes roughly 2-3 minutes per scoop before the crane returns to collect another batch of material. Then, once the barge is full, (and a barge can accommodate roughly 500 cubic yards before it becomes too heavy to navigate without grounding), it heads over to northern Ocracoke to transport the material via a pipeline to the designated spoil pit. There are two barges in operation with the current project, which means that work can go on continuously.

From there, a second contractor – Parks Land Development out of Elizabeth City, NC – transports the material from the spoil pit site to the dune line, building the protective and sandy border of N.C. Highway 12.

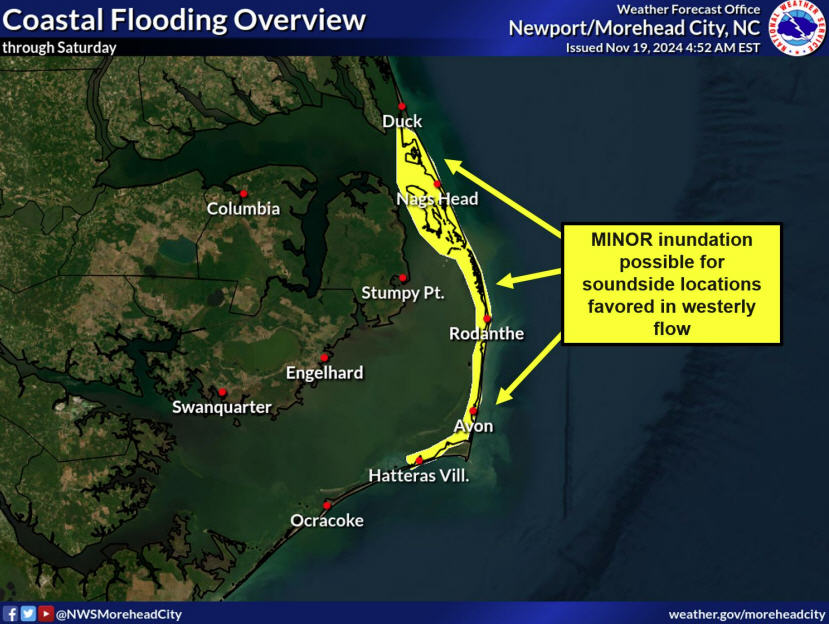

Meanwhile, all that sand removal from Sloop Channel, (which is essentially the only area where the emergency project is allowed to take place), is resulting in a deeper and wider route for the ferries, which have had trouble navigating in increasingly shallow conditions. Per recent reports, double-ended ferries, which draft more than the Hatteras class of ferries, have been temporarily put out of commission, as the shallow terrain from the Hatteras terminal to the Ocracoke terminal could damage the propellers. Deeper waters are more or less required to allow them to run once again.

The plan to address both issues at once is plugging along, but there have been some unforeseen and weather-related issues that have thrown a wrench in the works of the project’s productivity.

“We were originally hoping to have 70,000 cubic yards [of material] to both replenish the spoil site and rebuild the dunes so we wouldn’t run into this issue again,” said Tatum. “The original contract was for 55,000 cubic yards, which is what we were hoping for the dunes, and an additional 15,000-20,000 cubic yards for the pit [for future use.] But now, we lost some of the additional dune, so it may take more than the 55,000 to get the dunes back, so that will already cut into what we plan to stockpile in the pit.”

In addition, the bucket dredging operation can’t effectively work in seas greater than three feet, which equates to winds greater than 20 mph, depending on the wind direction, so weather delays are a constant concern as well.

In response to these concerns, last week the dredging operation started to operate 24 hours a day. Now, two crews will consecutively continue the work, operating constantly, to complete the 70,000 cubic yard goal before the designated March 31 moratorium. (As a quick background, dredging in Hatteras Inlet is allowed from October through March, although emergency dredging can be done in the months outside this window with special permission.)

“March 31 would right now be our last day available to dredge,” said Tatum. “There’s the chance that we can ask for an extension… if we don’t achieve the quantity to at least complete the dune.”

“At first, it was going slow,” said Lance Winslow, Assistant Director of Marine Asset Management for NCDOT. “But they have since been working 24 hours a day, and switched out the bucket they were using, so it’s looking pretty good now.”

“We are hoping to get this problem area [addressed] to make sure that the ferries can run this summer with no interruptions,” added Winslow.

Time will tell if the emergency operation can meet its goal of approximately 750 cubic yards of sand removal per day, which is a significant drop in the bucket to reaching a total goal of 70,000 cubic yards. But the fact that the first-ever bucket and barge operation is underway, and is addressing two needs at once, is a hopeful sign.

“This is an ongoing battle,” said Tatum. “Hatteras Inlet, Oregon Inlet… they are all battling the shifting sandbars every year, and it’s an ongoing process.”